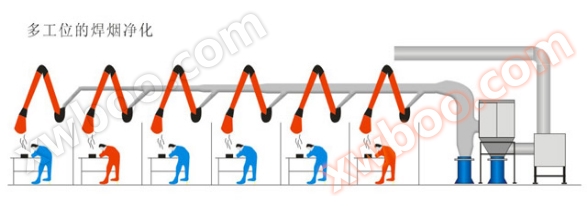

Centralized welding smoke purification system:

Process description:

Through the action of the induced draft fan, the smoke and dust generated in the workshop are instantly captured and collected by the capture device, and then enter the dust collector. The smoke and dust are intercepted and purified by the high-efficiency purification filter in the dust collector. The particulate matter adheres to the outside of the filter under the negative pressure of the fan. The pulse valve, under the control of the controller, automatically blows back the system filter from inside to outside at regular intervals to clean the dust. During the back blowing process, the particulate matter falls into the ash hopper for collection. After a certain amount of particulate matter accumulates in the ash hopper, it needs to be transported for treatment. The purified standard gas is discharged from the chimney.

Advantages of Central Welding Smoke Purification System:

The central welding smoke purification system is designed for working conditions with multiple welding stations, tight process connections, mixed processing of multiple processes, and relatively complex working conditions inside the workshop.

In the workshop, we adopt negative pressure absorption method, and each capture terminal will be designed with different terminal capture devices according to the actual working conditions. A suction hood can be set on the opposite or side of the polishing work area (or both), or a universal suction arm can be directly used to completely cover the dust source in the entire work area.

Beneficial for unified management and testing

case

The characteristics of a dust collector are as follows:

① Due to the pleated cylindrical shape of the filter material, the density of the filter material arrangement is high, resulting in a compact structure and small volume of the dust collector;

② The height of the filter cartridge is small, easy to install, and the maintenance workload is small;

③ The filtering area of the same volume dust collector is relatively large, the filtering wind speed is small, and the resistance is not high;

④ The folding of filter media requires strict sealing at both ends and no air leakage, otherwise it will reduce the effectiveness.

⑤ The filter cartridge uses imported polyester fibers as the filter material, adhering a layer of sub micron ultra-thin fibers to the general filter material. The arrangement of fibers on this adhesion layer is very tight, and the extremely small sieve holes can block most of the sub micron dust particles on the surface of the filter material;

⑥ Adopting automatic dust cleaning method.

⑦ High dust removal efficiency (up to 99.9%), easy to operate;